Achieving success in the age of product personalization requires a holistic approach. Everyone from sales and marketing, to engineering, to supply chain and manufacturing needs to be ready to participate in a faster, more detailed and collaborative process – with modern technology at the core. This is the first blog post of a 3-part series that examines how industrial machinery & equipment manufacturers can meet the increased demand for customized products.

The changes occurring in the era of the empowered consumer have rewritten the rules for customer engagement in virtually every industry, including manufacturing. Today’s consumers want to do business across multiple channels with a consistent experience, and they look for a highly tailored transaction that allows them to configure an order to their exact needs and specifications. This ongoing revolution means that configure-price-quote (CPQ) technology has become an increasingly important asset for meeting consumers’ higher expectations.

This 3-part blog series will uncover common product configuration challenges that industrial machinery and equipment manufacturers face and will describe how leading manufacturers are modernizing their product configuration processes in three key areas – sales and marketing, engineering, and supply chain and manufacturing. In this blog post, part 1, we will examine how sales teams can win more deals through an interactive configure, price, and quote process.

Download the Best Practices Guide: How to effectively design, sell, and deliver configured products

For many manufacturers, delivering a quote is a manual process that relies on outdated price sheets and often requires constant back and forth with product engineering and finance departments. This process is slow and inefficient, often resulting in missed opportunities that the customer would be interested in or losing the deal all together – not to mention the burnout that sales teams experience from the arduous process. In the competitive manufacturing industry, you simply cannot afford to stay with the status quo. Attempting to configure, price, and quote without integrated workflows and modern technologies could result in the following adverse outcomes:

- Inaccurate quotes

- Inability to extend your product set

- Losing deals to competitors

- Poor quality products that have incredibly long lead times

- Damaged customer relationships

Configuration automation and connectivity across sales, engineering and manufacturing could be the difference in winning a deal. Leading industrial machinery and equipment manufacturers rely on automation for configuration and quoting, which results in efficient processes, improved productivity, and increased sales. International Equipment Solutions (IES), a worldwide manufacturer of engineered attachment tools and cab enclosures for operator-driven equipment, has transformed their product configuration process with Infor CPQ. They’ve increased sales and sales-to-order conversion, while also freeing up capital that was previously stuck in generating quotes for custom orders. Leading manufacturers like IES provide their sales executives with access to dashboards and portals that display accurate information about available items and options, and configurations that are no longer supported and should not be selected. To maintain accuracy, they use a robust configurator tool that is linked with engineering and supply chain data.

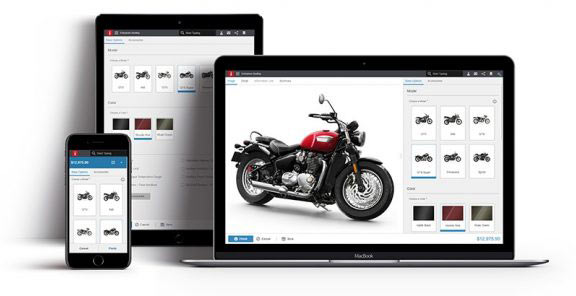

From the customer’s perspective, the configuration process is simple. Leading manufactures who have modernized their configuration and quoting process allow the customer to get a quote the way they want to – whether they are calling a salesperson or using a dedicated customer portal. If they choose to call the manufacturer directly, the salesperson can walk them through available options and generate a quote immediately. Or, they can use the customer portal to see available options, what they look like, make changes, and automatically be presented with a quote. No matter what option the customer chooses, the process is seamless, allowing them to see what they’re going to get, when they’re going to get it, and how much it’s going to cost. And ideally, they could pay right there.

Stay tuned for part 2 of our 3-part blog series on achieving product configuration success.